|

Zhengzhou Tongxing Air Conditioning Technology Co., Ltd.

|

Bolivian filament air hose

| Price: | 7.0~15.0 RMB |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

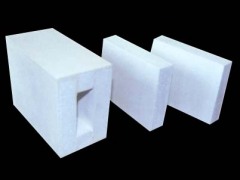

Fiberglass composite duct is a kind of high intensity duct, taking the centrifugal glass wool as material,with high quality and favorable price.

Antibacterial fiberglass composite duct utilizes centrifugal glass cotton as the raw material, internal and external walls uses different type composite materials, and high viscosity glue with water capacitive, featuring with good thermology and acoustics effects. The application of fiberglass composite duct achieves a new stage, especial in the field of air conditioning. For one thing, fiberglass composite duct overcomes the shortcomings of other similar products because of the unique materials and exquisite technology. For another, comparing with the traditional ducts, it saves the investments in piping systems about 20%.

Special functions;

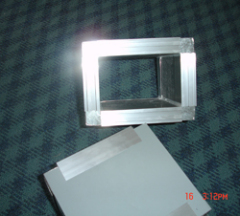

1. sound-absorbing performance.

The inside surface utilizes punched thin sheets or (boxian cloth and glass fiber vinyl coating adhesive sealing cotton), porosity from 25% to 30%, simple perforation plate with 5 mm diameter, and has unusual sound-absorbing performance.

2. Conservation

Centrifugal glass board through a unique craft processing, thermal conductivity is less than0.033 W/M.K, reflecting its superior insulating performance, thereby can save energy.

3.Health protection:

Through a series of rigorous tests on this kind fiberglass vent -pipe glue, our company proves that there is no formaldehyde, and the fiberglass composite duct complies with the standards of hygiene and safety

4. Antibacterial

Perforation plates or fiberglass duct contains water-soluble antimicrobial agents and the stable molecular structure, thus can inhibit the growth of bacteria and moulds. Surface material tested by the national related departments proves that it has antibacterial proofing property

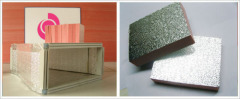

Features:

1.Light texture, easy making,

2.clean and environmental protection,

3.heat preservation and sound insulation, reach the fireproof standard of Level-A,

4.elegant and durable, non-toxic, safety use,

5.disposable investment, no maintenance fees.

2.clean and environmental protection,

3.heat preservation and sound insulation, reach the fireproof standard of Level-A,

4.elegant and durable, non-toxic, safety use,

5.disposable investment, no maintenance fees.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!